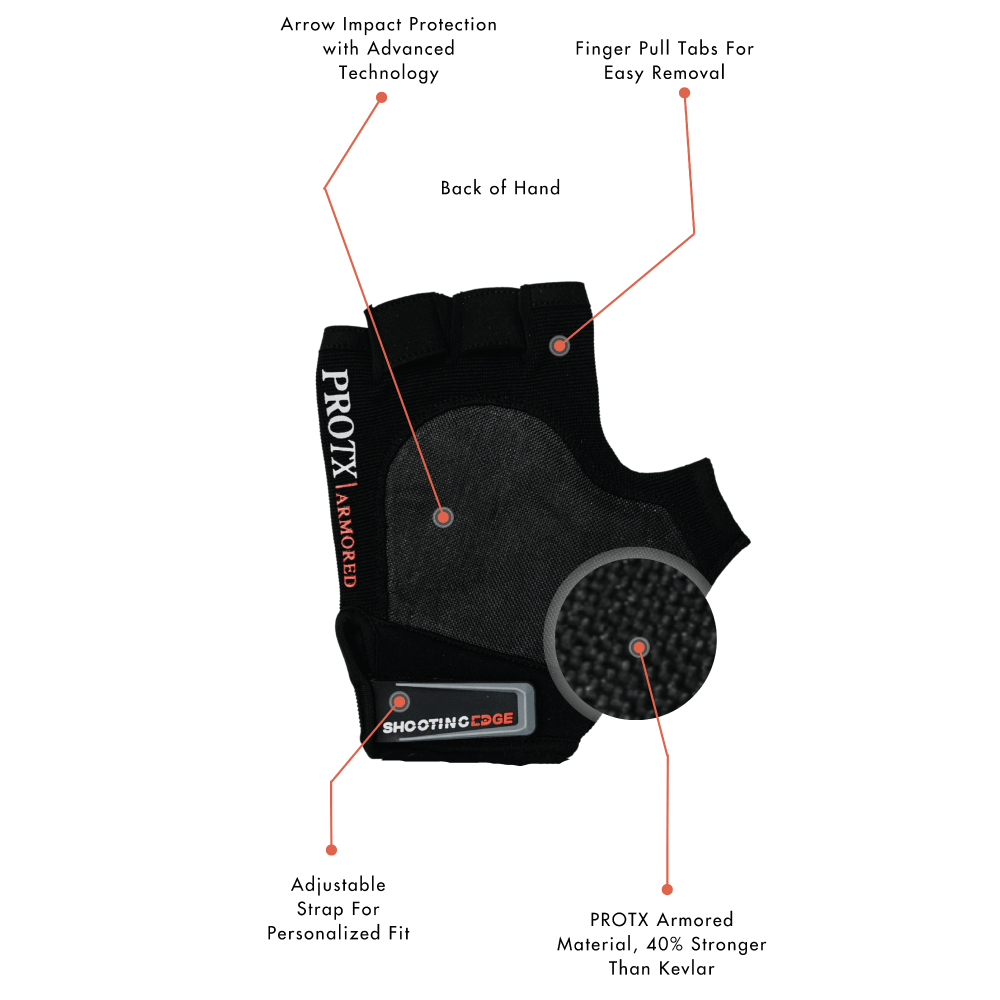

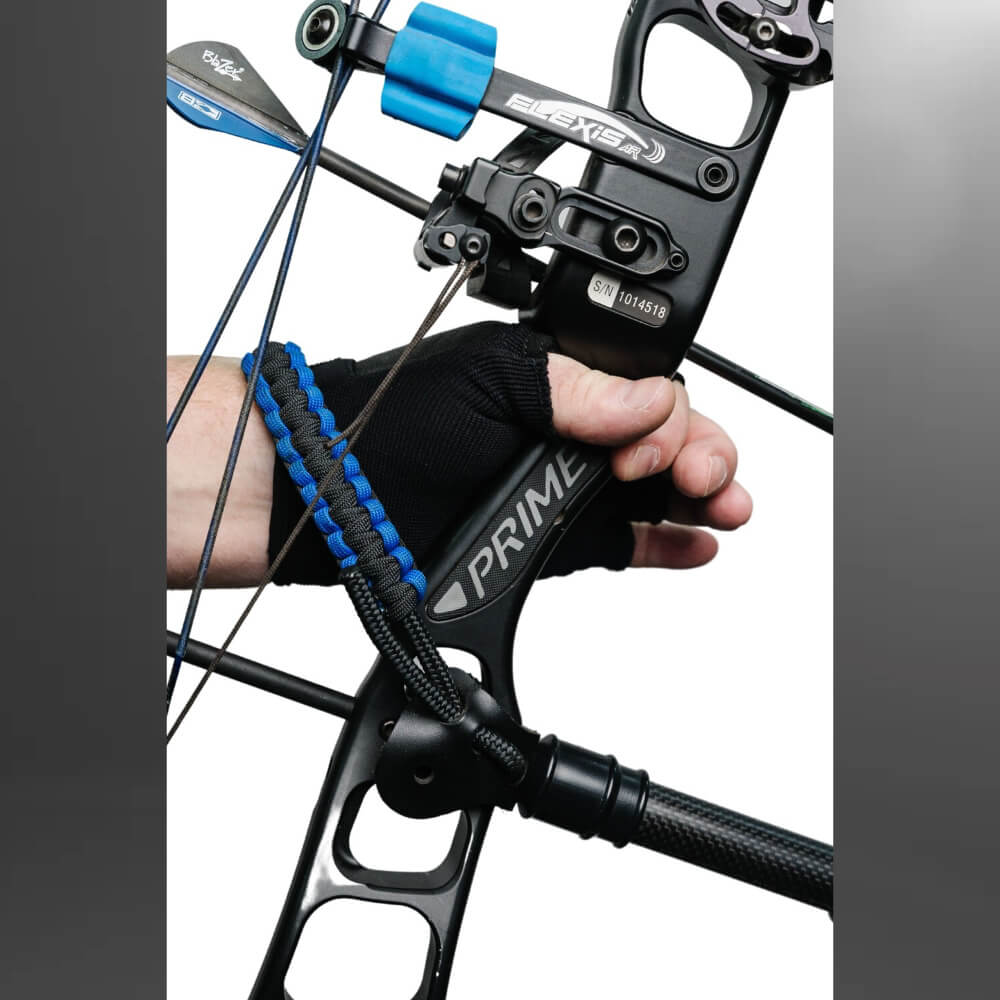

Description

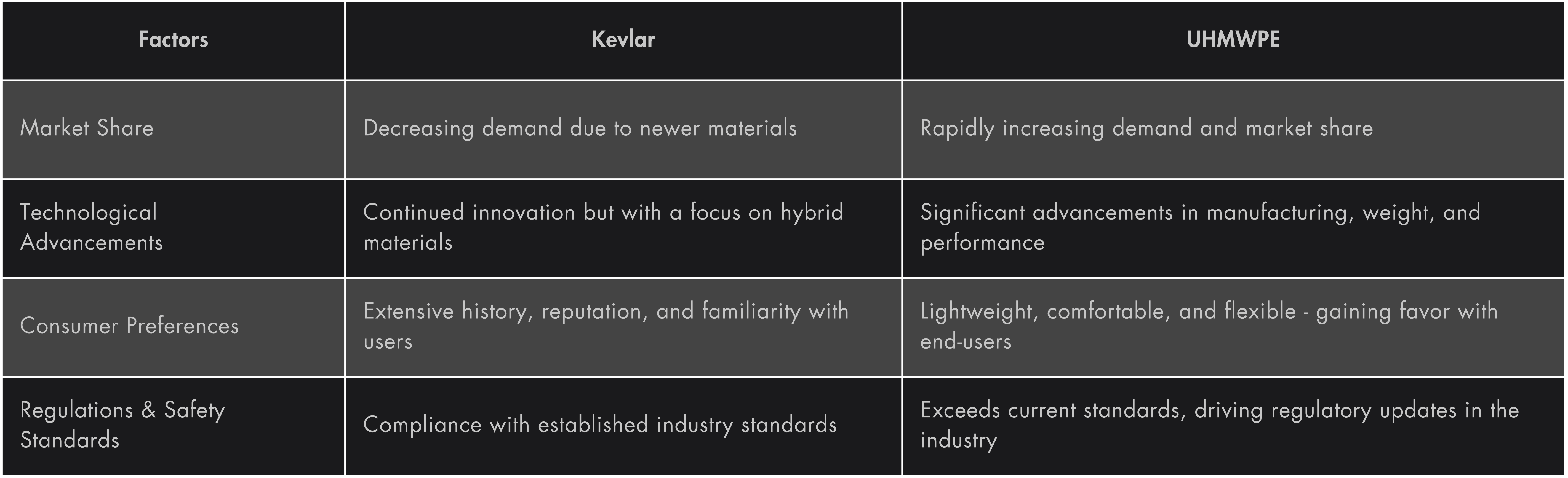

Comparison of UHMWPE vs Kevlar

In the world of protective gear materials, UHMWPE and Kevlar are frequently compared due to their prominence and widespread use in the industry. To better understand their positioning in the market, we’ll examine their properties and analyze factors such as strength, weight, and flexibility.

Strength: One of the key attributes that set UHMWPE apart from Kevlar is its outstanding strength. On a pound-for-pound basis, UHMWPE is 15 times stronger than steel. In comparison, Kevlar is 5 times stronger than steel, also showcasing impressive strength.

Strength: One of the key attributes that set UHMWPE apart from Kevlar is its outstanding strength. On a pound-for-pound basis, UHMWPE is 15 times stronger than steel. In comparison, Kevlar is 5 times stronger than steel, also showcasing impressive strength.

Weight: Another notable difference between UHMWPE and Kevlar is their respective weights. UHMWPE is lighter than Kevlar, making it a more attractive choice for applications where weight is a crucial factor, such as in body armor and protective gear for law enforcement, military personnel, sports professionals.

Flexibility: When it comes to flexibility, both UHMWPE and Kevlar offer a high degree of flexibility. However, UHMWPE is known for being more flexible, making it the preferred choice in situations where wearers require increased mobility and comfort.

Kevlar vs. UHMWPE: Analyzing Performance in Protective Gear

Ballistic Resistance

The ballistic resistance comparison between Kevlar and UHMWPE is a critical factor in evaluating their effectiveness in wearable protection gear. Both materials have demonstrated remarkable performance in bulletproof vests and other ballistic-resistance applications. However, UHMWPE has a higher strength-to-weight ratio, resulting in lighter and thinner protection solutions without compromising on resistance. This is particularly important for military and law enforcement personnel who require maximum protection with minimal added weight.

Comparing Kevlar and UHMWPE, ballistic test results show that UHMWPE generally outperforms Kevlar in terms of both bulletproof vests’ performance and weight reduction.

Comfort and Flexibility

Comfort in body armor and flexibility of ballistic fibers are essential factors in determining the wearability and effectiveness of protective gear. Kevlar is known for its flexibility, making it highly suitable for a wide range of applications. However, due to its higher strength and lower density, UHMWPE allows for more flexible, lightweight solutions. This can provide end-users with increased mobility and comfort, particularly crucial for those who need to wear body armor for extended periods of time.

Market Trends of UHMWPE and Kevlar

There are no reviews yet.